Working in South America (a historical summary, part 3)

In December of 2010 I was laid off from one of the largest BMX companies in the world. I decided it would be a great time to focus on my own business, the only problem was I didn’t know what I was doing. I had ideas for the clothing, but I didn’t know how to make it a reality.

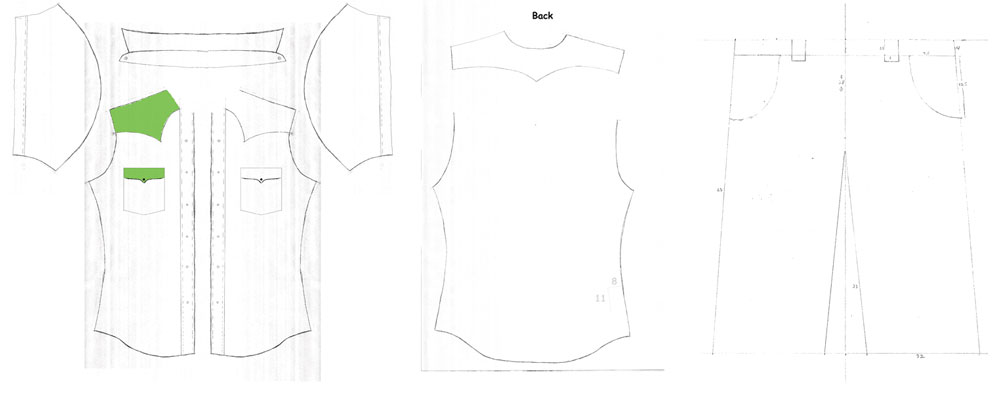

I spent about two months developing “sketches,” colorways, and patterns. I bought a thread-puller and painstakingly took apart my favorite shirt so I could mimic the fit. This was very helpful from a brainstorming perspective, but completely pointless from a production standpoint.

Southern California was too expensive so I hopped a flight to Ecuador and spent a month sitting on the beach and sifting through the international trade website Alibaba.com.

If you’re trying to make a product that’s already been made and just want to make minor tweaks then Alibaba, and similar trade sites, are amazing. Unfortunately, I spent most of my time beating on a brick wall. The language barrier was a huge problem, as was the culture of innovation in larger factories.

A particularly frustrating exchange occurred this way:

· I emailed a factory asking if they could make a “western” or “cowboy” shirt. I specifically said my garments could not have ANY cotton.

· The factory said it was no problem to source 0% cotton fabrics

· I asked if they could send me pictures of the shirts they had made in that style.

· The factory sent me several pictures of decent looking shirts in the style I wanted. They were a little square, but I thought I could tweak the design so they had more taper and would fit a cyclist’s body type better.

· I asked what the fabric content was.

· The factory said “100% cotton” as if that was a mark of their superior quality

The factories thought that if I wanted bike apparel I must want lycra road gear, and if I wanted casual apparel then their 100% cotton fabric would be the most cost efficient and comfortable option. With my experience and vocabulary, there was no way to convey that I didn’t want either of these.

Leave a Comment